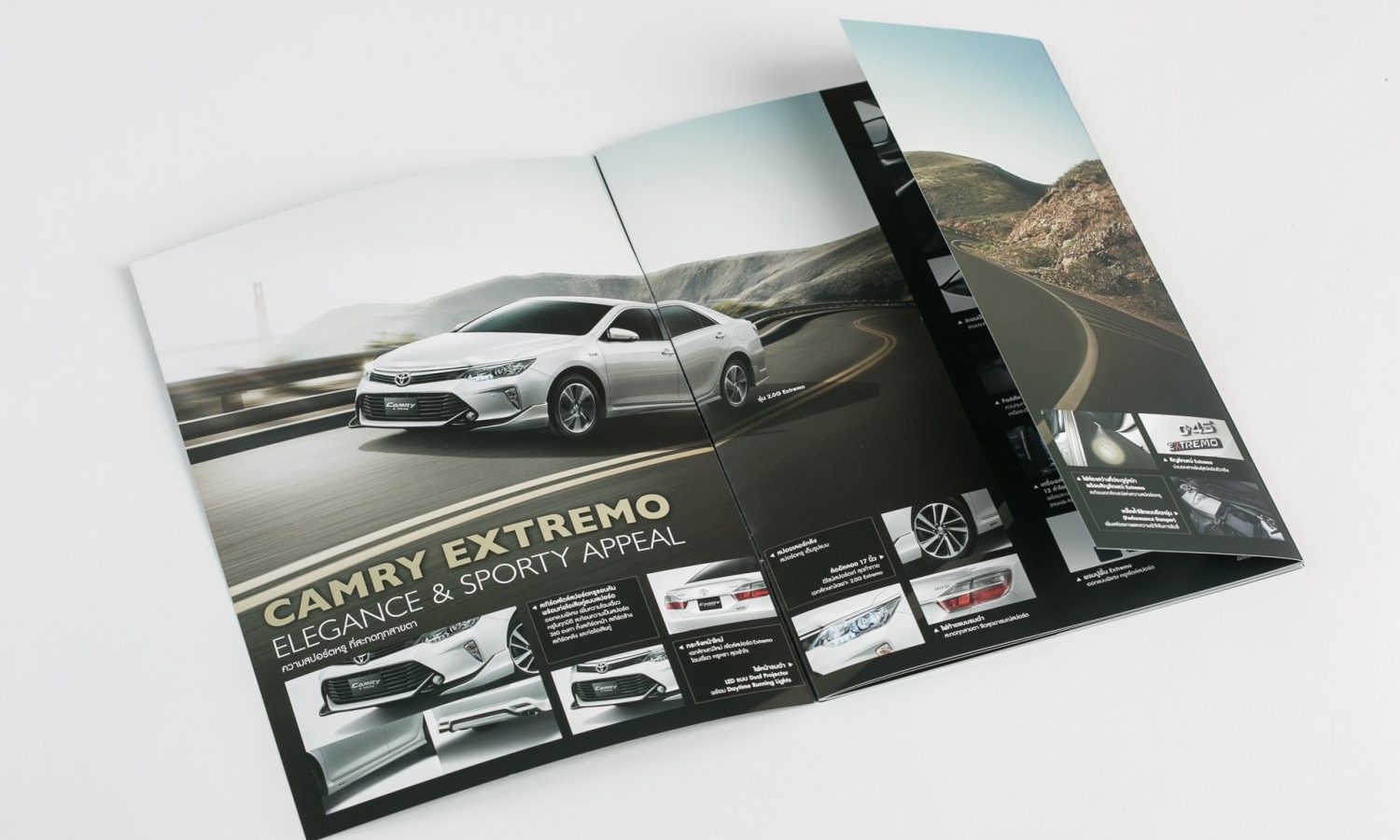

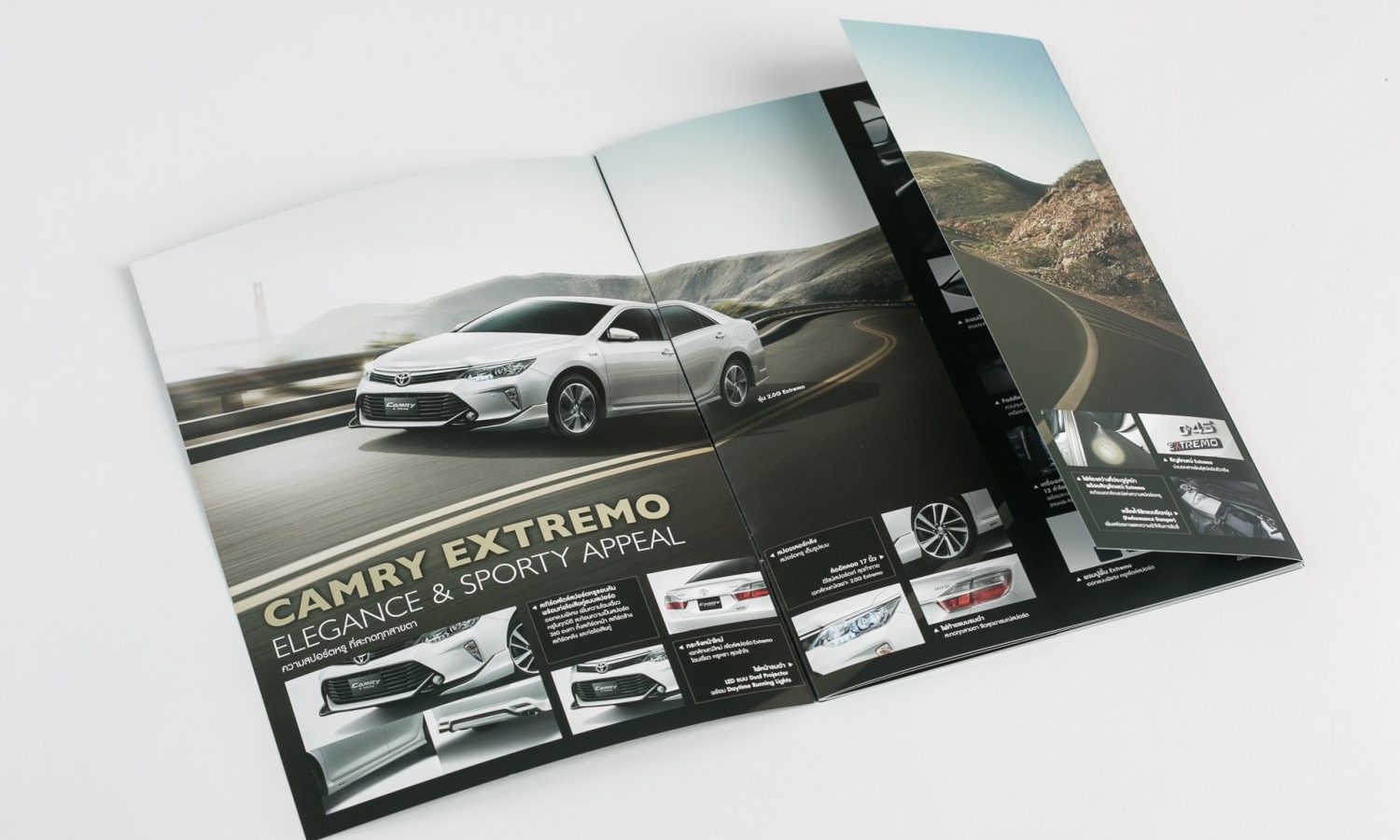

Why print catalogs ?

The Print Catalog is effective as a more targeted strategy. With stronger databases and a greater knowledge of their buyers, retailers are able to target customers much more effectively than ever.

The Print Catalog is effective as a more targeted strategy. With stronger databases and a greater knowledge of their buyers, retailers are able to target customers much more effectively than ever.