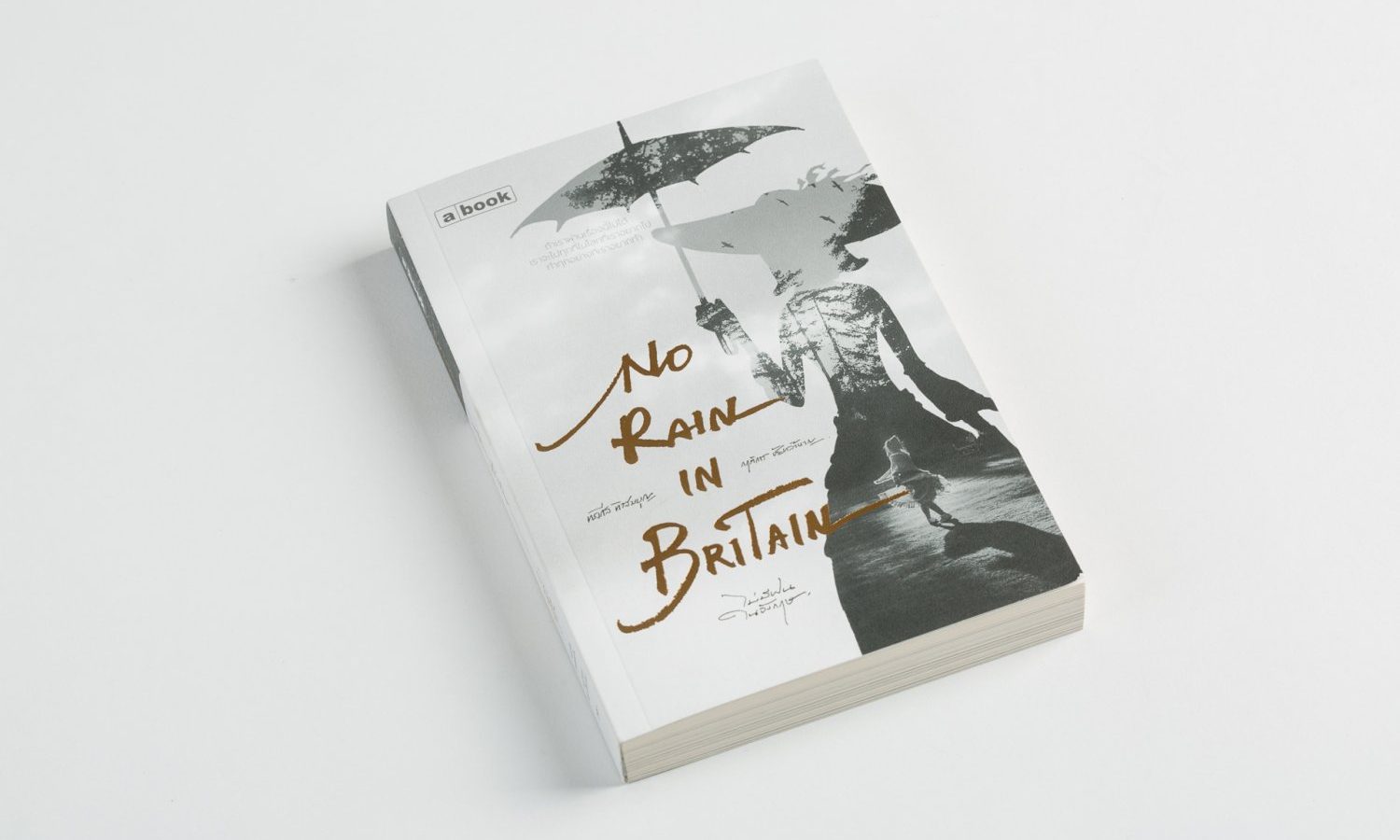

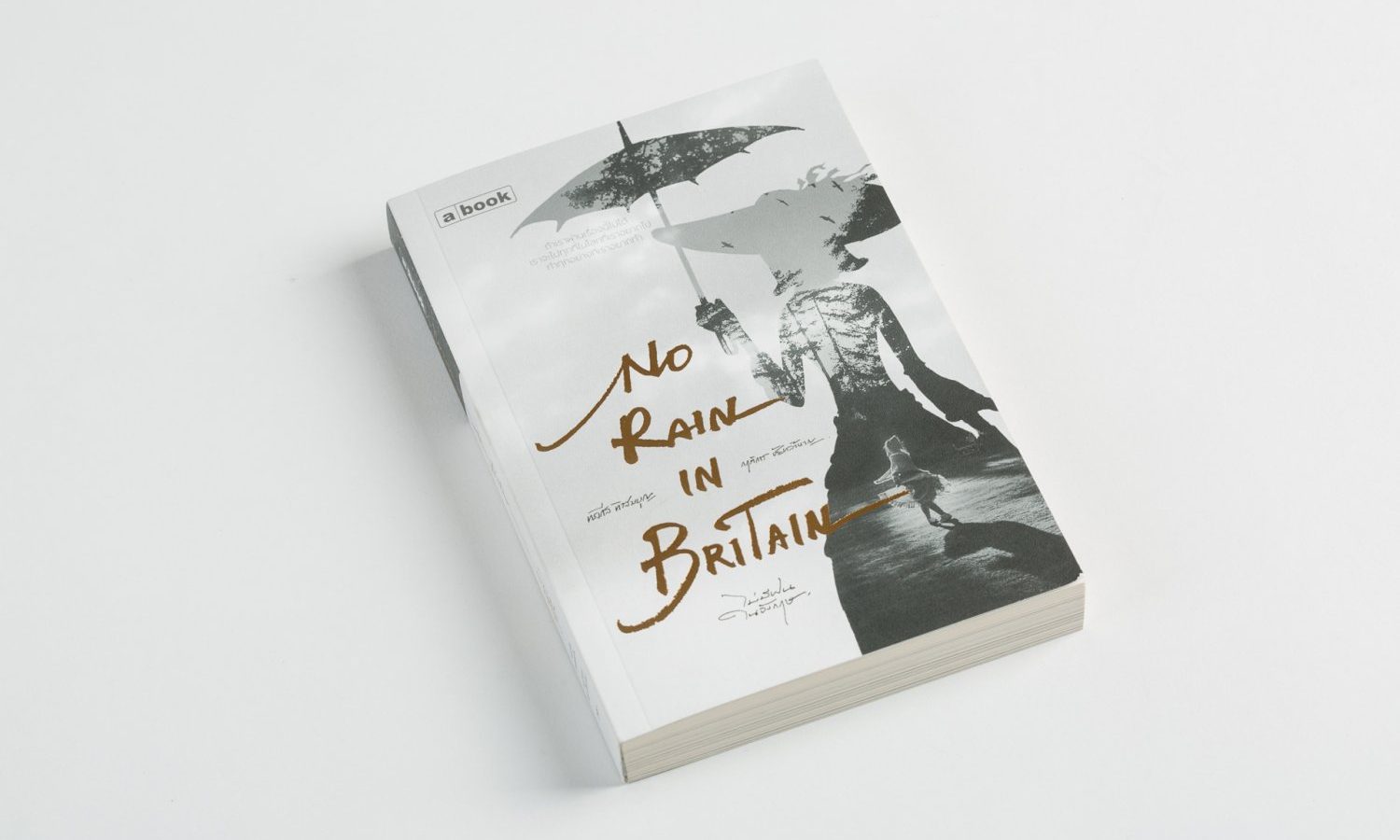

Why print books ?

Readers of print books absorb and remember more of the plot than readers of e-books do. Readers also understand more of the narrative.

Readers of print books absorb and remember more of the plot than readers of e-books do. Readers also understand more of the narrative.